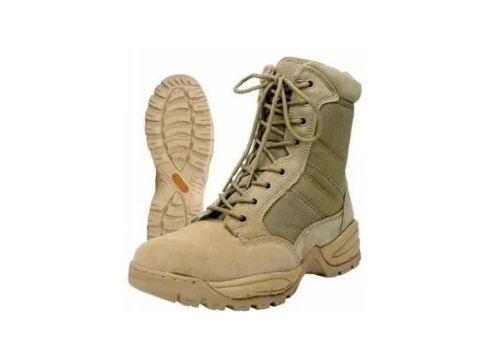

The Cement Process is a traditional and widely used method in shoe and footwear manufacturing, where the outsole is directly bonded to the upper using strong adhesives. This technique allows for flexible, lightweight, and cost-effective shoes while maintaining reliable durability for daily wear. Cemented shoes are ideal for casual, athletic, and work footwear where comfort and production efficiency are priorities.

Key Features

-

Lightweight & Flexible: Direct bonding ensures a flexible sole without added bulk.

-

Cost-Effective: Efficient production process suitable for mass manufacturing.

-

Reliable Bond: High-quality adhesives provide strong attachment between upper and sole.

-

Versatile Materials: Compatible with leather, synthetic, rubber, and EVA soles.

-

Fast Production: Short curing times compared to stitched constructions like Goodyear welt.

Product Specifications

| Feature | Details / Options |

|---|---|

| Construction Type | Cemented / Adhesive Bonding |

| Upper Material | Leather, synthetic leather, fabric, mesh |

| Sole Material | Rubber, EVA, PU, Thermoplastic |

| Adhesive Type | High-strength polyurethane or EVA-based glue |

| Durability | Suitable for casual, athletic, and work footwear |

| Flexibility | High flexibility for comfort and natural foot movement |

| Sizes Available | Standard men’s and women’s sizes (custom sizes optional) |

| Applications | Sneakers, casual shoes, work shoes, children’s footwear |

| Production Efficiency | Fast curing and assembly for mass production |

Applications

-

Casual and lifestyle shoes

-

Sports and athletic footwear

-

Work and safety shoes

-

Children’s shoes and school footwear